Cutting Gemstones

The cutting process is complex, detail-intensive, and essential for the creation of a valuable stone.

Here we will focus on cutting a diamond but the process is the same for precious and semi precious stones.

Obviously the first step of diamond cutting is obtaining a rough diamond – the raw, uncut stone freshly extracted from the ground by use of various methods such as Alluvial or Pipe mining. Like a marble statue, this raw diamond will eventually be whittled, cut and polished down to a brilliant work of art.

The second step, and perhaps the most important, is planning the design the diamonds will be cut into. For this step, size and shape of the rough diamond is considered, as well as the diamond market into which it will be released. Different sizes, colors and weights fetch different prices and hold different intrinsic value, so the diamond cutter must be wise in both timing and skill! In modern times, 3-D imaging software is often used to determine the most optimal cut. For a more in-depth list of different cuts and their histories, stay tuned for future articles!

The third step is the initial cutting of the rough diamond, known as “cleaving”. The rough is cut into multiple pieces, each one destined to be cut into a predetermined design. This process involves incasing the rough diamond in cement, and laser-cutting the diamond into smaller segments. The segments are then separated by chisel, and subsequently removed from the cement.

The final steps are the processes by which diamonds are shaped into the characteristic forms which are most familiar. The first of these finishing steps is called “bruting”. Diamonds of a similar shape and size are set against each other in a specialized machine, which then grinds the crystals against each other until they are worn down to the desired size. About 50% of their original weight is lost from the diamonds during this process.

The next finishing step is known as “polishing”. This process looks similar (and has a similar effect) to a carpenter sanding wood. The diamond is placed against an abrasive wheel, spun at high speed, which wears reflective facets into its surface. After this, the finished diamond is cleaned and inspected for sale.

was created by the Asscher Diamond Company and was originally introduced in 1902. During the 20’s the cut became very popular but with the effects of the Great Depression its popularity diminished. For many years this stone was found mostly in vintage jewelry shops but enjoyed renewed interest in the early years of this century.

was created by the Asscher Diamond Company and was originally introduced in 1902. During the 20’s the cut became very popular but with the effects of the Great Depression its popularity diminished. For many years this stone was found mostly in vintage jewelry shops but enjoyed renewed interest in the early years of this century. hion. The profile of the stone is a little more broad and deep than other cuts. Its breathtaking beauty requires careful selection. Because of the large table of the stone, small imperfections and inclusions are more visible than in other cuts so it is wise to choose with attention to detail.

hion. The profile of the stone is a little more broad and deep than other cuts. Its breathtaking beauty requires careful selection. Because of the large table of the stone, small imperfections and inclusions are more visible than in other cuts so it is wise to choose with attention to detail.

The Emerald cut is also known as a Step cut and is an historical old cut with a rectangular table or top and symmetrical steps along the sides cut in parallel steps. It was originally designed to showcase the color of emerald stones and is now used for most other gemstones due to the cut’s sheer elegance. The name “Emerald Cut” was not used until the 1920’s, when the sensibilities of Art Deco became en vogue.

The Emerald cut is also known as a Step cut and is an historical old cut with a rectangular table or top and symmetrical steps along the sides cut in parallel steps. It was originally designed to showcase the color of emerald stones and is now used for most other gemstones due to the cut’s sheer elegance. The name “Emerald Cut” was not used until the 1920’s, when the sensibilities of Art Deco became en vogue. a set pattern while today’s standardized Emerald Cut is usually a rectangle with a total of 58 facets having 25 on the Pavilion, 25 on the Crown, and 8 on the Girdle, with three rows of top steps and three rows of bottom steps.

a set pattern while today’s standardized Emerald Cut is usually a rectangle with a total of 58 facets having 25 on the Pavilion, 25 on the Crown, and 8 on the Girdle, with three rows of top steps and three rows of bottom steps.

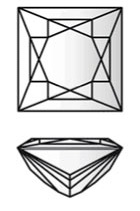

The Princess cut is considered a mixed cut and has a square shape. The cut features a unique chevron-shaped pavilion faceting paired with table facets cut similar to a round brilliant, and combined with the unique pyramid shape helps create greater light dispersion.

The Princess cut is considered a mixed cut and has a square shape. The cut features a unique chevron-shaped pavilion faceting paired with table facets cut similar to a round brilliant, and combined with the unique pyramid shape helps create greater light dispersion.

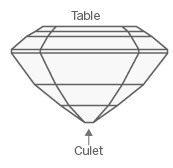

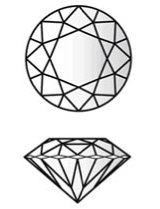

cal “diamond” shape, with a large, circular top (the ‘Table’), with a short base (the ‘Crown’), a wide brim (the “Girdle”), and a cone-like drop (the ‘Pavilion’) into a final point at the bottom (the ‘Culet’). The standard number of refractive facets cut into the stone is around 33 (for the crown) and 25 (for the pavilion), though these sometimes vary in size and number, leading to some contention within the gem cutting community.

cal “diamond” shape, with a large, circular top (the ‘Table’), with a short base (the ‘Crown’), a wide brim (the “Girdle”), and a cone-like drop (the ‘Pavilion’) into a final point at the bottom (the ‘Culet’). The standard number of refractive facets cut into the stone is around 33 (for the crown) and 25 (for the pavilion), though these sometimes vary in size and number, leading to some contention within the gem cutting community.